View the Electromaax line of High Output Marine Watermakers. We produce an industry leading marine watermaker with patented energy recovery features that meet the needs of boaters everywhere. Ultra-quiet, high-output water system with the lowest TDS, highest energy efficiency, most compact design, with easy maintenance, and military-grade components.

Showing all 6 results

-

DIY Base Utility 12/24 Volt 200GPD Marine Watermaker

$5,298.00 -

Sale!

Solarmaax Tropic 200GPD Compact 12/24 Volt Marine Watermaker

Original price was: $6,395.00.$5,116.00Current price is: $5,116.00. -

Solarmaax World 200GPD 12/24 Volt Marine Watermaker

$6,395.00 -

Solarmaax World 340GPD 12/24 Volt Marine Watermaker

$7,888.00 -

Sale!

Solarmaax World 340GPD Compact 12/24 Volt Marine Watermaker

Original price was: $8,295.00.$5,988.00Current price is: $5,988.00. -

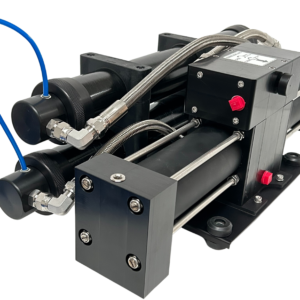

Warranty Rebuild Exchange Program for Clark Pump

$887.00