Date: August 9, 2023

Date: August 9, 2023

Location: St Maarten

In our continuous quest to improve the cruising experience aboard our Leopard 43, Peregrine, we’ve implemented several modifications. This edition will focus on the integration of high-output alternators, and our upcoming issue will delve into the addition of a marine water maker.

The Evolution of our Charging System

Upon acquiring Peregrine, she was equipped with the stock Hitachi 80A internally regulated alternators on both engines. These alternators were tasked with charging both the start and house batteries via solenoids that activated once the alternators initiated power production.

For enhanced control over the charging process, especially with our augmented solar array, we revamped the engine charging system. We incorporated two Electromaax Cruisers 140A externally regulated alternators paired with Balmar 614 regulators.

Additionally, two Balmar Duo-charge units were integrated to ensure the start batteries received optimal charge from the house bank.

This system provided satisfactory performance, especially with our Lifeline AGM batteries but as these batteries approached the end of their lifespan after nine years, a transition to Lithium batteries was in order.

Adjusting the Charging Parameters

Adjusting the charging parameters in our Classic solar charge controller was essential for compatibility with the lithium batteries. The advantage of lithium batteries lies in their ability to accept charge at rapid rates consistently, unlike lead-acid batteries. Consequently, to reduce engine runtime, we wanted our engine alternators to charge the lithium bank as swiftly as possible.

Overcoming Challenges with Heat Dissipation

Given the heat generated during the charging process, alternator efficiency became a primary concern. To combat the heat, particularly in compact alternators, some manufacturers have started relocating the rectifier diodes. By doing so, the heat that the alternator fan blades need to dissipate decreases, thus enhancing alternator output.

To augment our system, we transitioned from the Cruiser alternators to Electromaax 250A Genmax alternators with Remote Rectification (RR).

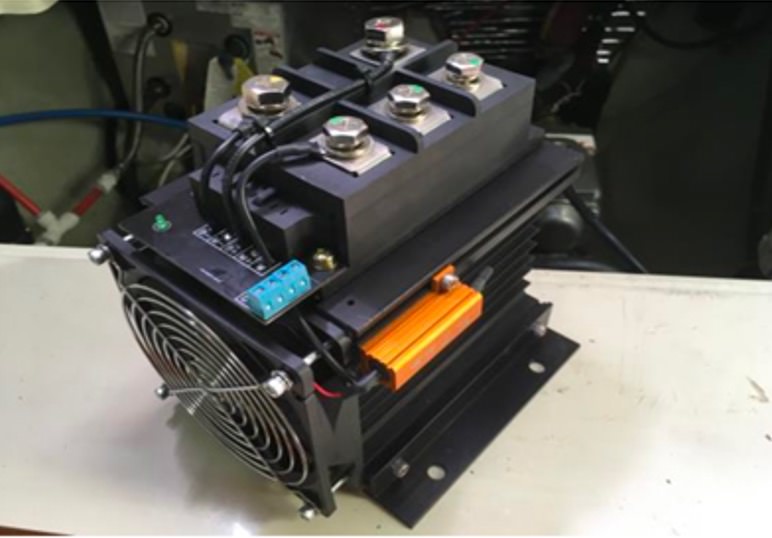

- Figure 1: Remote Rectifier unit displaying the 3 terminals for the alternator 3-phase wiring alongside the DC+ and DC- cables.

- Figure 2: A comparison of the previous Cruiser alternator (silver) with the upgraded Genmax alternator (black).

- Figure 3: The newly installed alternator on one of the Yanmar 3JH4E engines, accompanied by the RR unit with red protective boots.

Electromaax Remote Rectifier

Cruiser and Genmaax Marine Alternator

New marine alternator mounted

For longevity and optimal battery health, we modulated the alternator outputs, ensuring that charging currents remained below 0.5C.

In light of the challenges with the Balmar 614 regulators, we’ve transitioned to an Electromaax AT3 regulator, although we’re currently assessing its performance. Potential alternatives like the Electromaax Pro X regulator and the Wakespeed WS500 are being considered.

As our start batteries (one flooded and one AGM) have distinct charging profiles, which differ from the lithium profile, we replaced the Duocharge units. Now, we utilize a pair of Victron Orion 18A Battery To Battery (B2B) chargers, offering tailored charging parameters for each start battery.

About the Author:

CYOB’s Boat Nerd, Mike Wheatstone, has had a passion for sailing since his adolescent years. Purchasing his first boat, a Shark, in 1980, he gradually upgraded to bigger models with the growth of his family. Now a retired electrical engineer, Mike and his wife relish their summers on their Hunter (Dragonfyre) and the Caribbean winters aboard their Leopard 43 catamaran, Peregrine.