Here’s an install of several Electromaax upgrades to a Nova Marine Trawler with twin Volvo TMD41A diesel engines. As our customer points out there were several challenges with this significant upgrade but well worth it. They did a great job with documenting the upgrade and provided the following information and pictures:

Here’s an install of several Electromaax upgrades to a Nova Marine Trawler with twin Volvo TMD41A diesel engines. As our customer points out there were several challenges with this significant upgrade but well worth it. They did a great job with documenting the upgrade and provided the following information and pictures:

Nova Marine Trawler – Twin Volvo TMD41A Diesels

Several challenges, but ultimately all is working as planned with this significant upgrade. A detailed accounting follows to assist others considering a similar project.

Problem Statement

Chronically undercharged house-bank when away from shore power. The four 6VDC Golf Cart Flooded Lead Acid house-bank batteries were in dire need of replacement, however the engine Alternator set-up would likely soon degrade new batteries.

Each engine was equipped with a stock internally regulated dual V-Belt Alternator with a nominal 50-Amp maximum output. The Alternators were measured to be outputting less than 14 VDC which would lead to chronic under-charge of the lead acid batteries. Further, only one Alternator was connected to charge the house-bank while the other Alternator charged the engine start battery. Using just one low-amperage under-voltage Alternator would take many hours (7+) of motoring to fully recharge the house-bank after a day away from shore power.

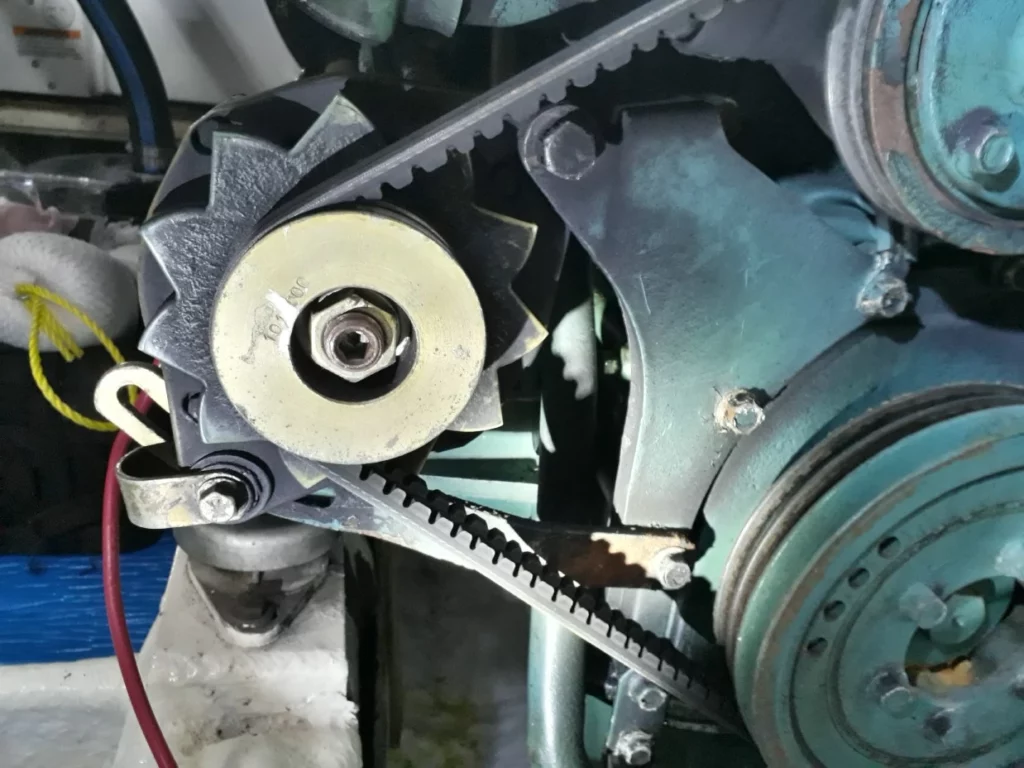

Belt Dust Covered Original Alternator

Project Scope

Batteries. Replace Flooded Lead Acid house-bank with LiFePO4. Alternators.

Replace both engine Alternators with Electromaax Cruiser 140-Amp alternators, including engine pulley upgrade kits and all associated E-MAAX PLUS charging sensors and computers

Pulley Kit

Removed port engine Alternator, Coolant Pump Pulley, and Crankshaft Pulley and forwarded to Electromaax to assure the custom-made Pulley Kit would fit and install without issue. The Crankshaft Pulley cover fit perfectly and installed without issue. Lesson-learned: to press-fit on the replacement Coolant Pump Pulleys the pumps had to be removed from the engine to assure the pumps’ shaft was not pushed back causing friction and restricted rotation.

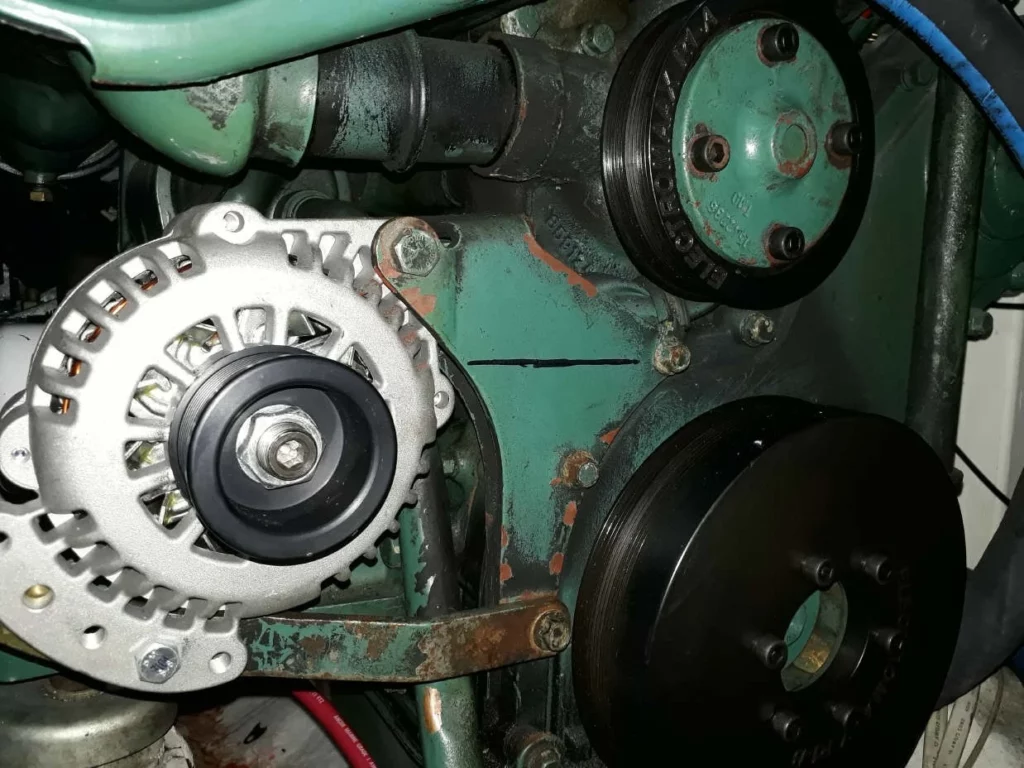

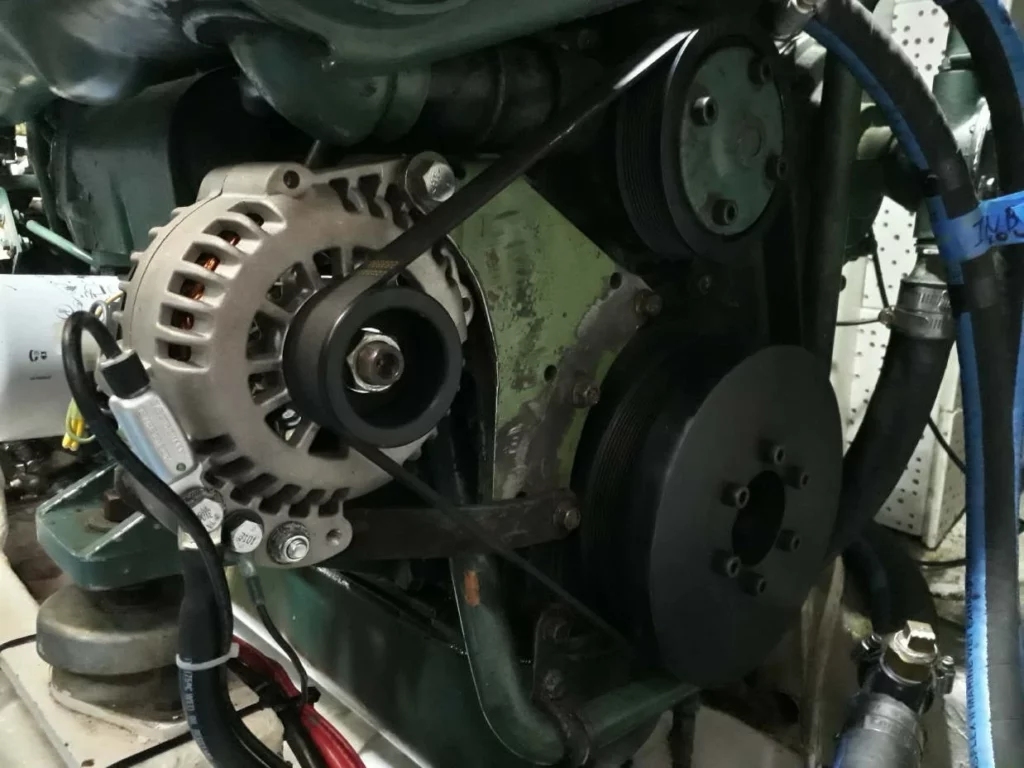

Alternators

Changed the boats’ charging design so that both Cruiser 140-Amp alternators would combine to charge the house-bank batteries.

Mounting the new Cruiser 140-Amp alternators was the most significant challenge. The proximity of the new Alternator to the engines’ raw water and coolant piping provided less than an inch of arc-travel to slip on and tighten the Pulley Kit J-Belt. A 44-inch belt was too large to tighten, while a 43.5-inch belt was too small to pull over all three pulleys.

Corrective Actions:

(1) The 5/16” diameter aluminum pivot bearing that came with the Cruiser 140-Amp alternator was drilled out to 3/8” to accept the engines’ original pivot bolt (as the retaining nut for a 3/8” bolt is welded to the Volvo Alternator foot-mount).

(2) To provide sufficient alternator swing-room to install and tighten a J-Belt, an extra inch of material was welded to the Alternator Mounts to move the alternators laterally outboard. As more swing room was still required, approximately ¼” of material was removed from the mounts adjacent to the Alternator. A J-Belt could now be installed and tightened without the Alternators contacting the surrounding engine

Little Alternator Swing Room

Original Mount/Insufficient Swing Room

Welded Added Material (Duplicate Holes)

Pulley Kit and Alternator – Added Swing

The engine start battery is no longer charged from an engine Alternator, but by the boats Generator alternator (away from shore power), or a DC Charger (shore power or via the Generator). Concerned with depleting the engine start battery during a long day of cruising, a digital voltmeter was installed at the helm to closely monitor the engine start battery. All summer, including long days of multiple dual-engine starts through the Rideau Canal, the engine start battery never dropped below a charge of 12.4 VDC. Still, we will be watching product developments at Electromaax to possibly install a programmable Voltage Sensing Relay to charge the lead-acid engine start battery from the engine Alternators (>13.5VDC) but assure the engine start battery is disconnected from the LiFePO4 House-Bank when the Alternators are not charging (<13.4 VDC).

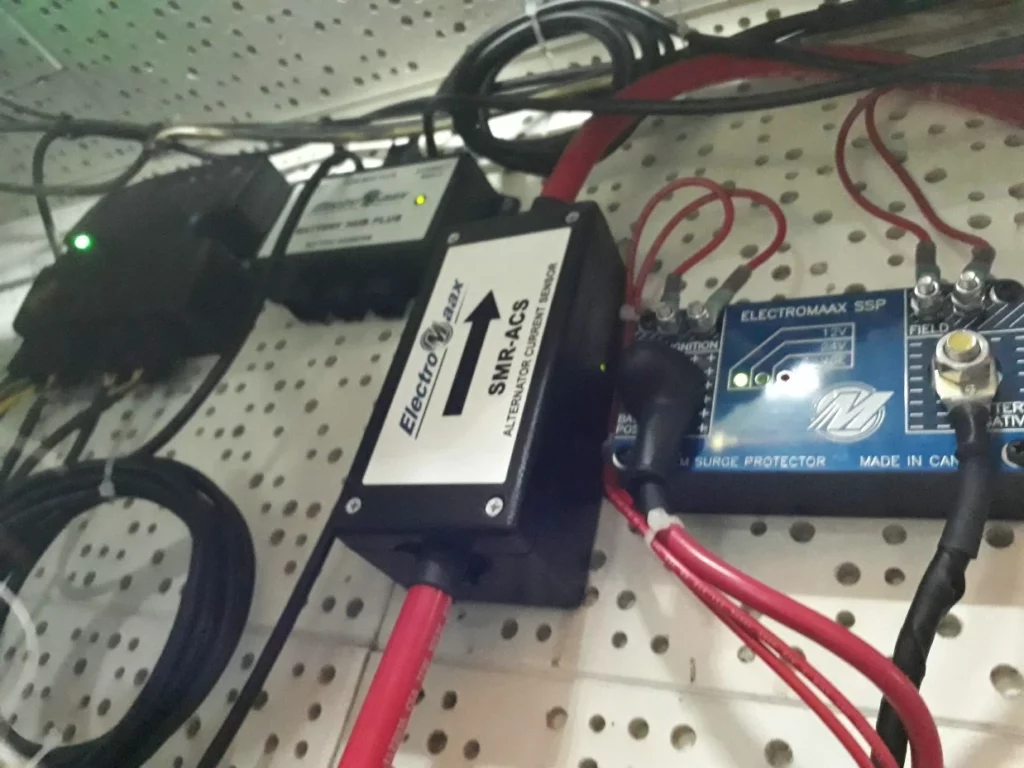

Charging Computers and Sensors

The Electromaax documentation and well-designed interconnections made the E-MAAX PLUS installation extremely straight forward.

Corrective Actions:

(1) Though there is no intention to use the full 140-Amp output of the Alternators, their output was connected with 1 AWG wire to be safely able to conduct full output. The Electromaax enclosures for the Current Sensors do not have openings large enough to accommodate 1 AWG wire with crimped and shrink-wrapped Lug. A Dremel tool was used to enlarge the openings to the Current Sensors.

(2) My mistake, the output of the Alternators must be connected to a terminal between the Electromaax Battery Current Sensor and the batteries. Electromaax was instantly able to diagnose why the Electromaax User System Interface (USI) program was reporting double the expected Alternator charging output.

Port Engine & Common Equipment

LiFePO4 Batteries

Four 232 Amp-Hour 6VDC Golf Cart lead acid were initially replaced with three Electromaax G31 LiFePO4 114 Amp-Hour batteries. Thereby changing the house-bank capacity from a nominal (464A x 50%) 232 Amp-Hours to (342A x 80%) 274 Amp-Hours; with a weight and space savings.

Away from shore power, it is likely rare that one will devote the many hours to fully re-charge lead-acid batteries back to a 100% float charge, which otherwise will lead to a reduction in battery capacity and life. The 0.6 charge rate of the LiFePO4 enables charging to a maximum of 3 x 114A x 0.6 = 205 Amps which would fully replenish 274 Amp-hours in less than 90 minutes of motoring.

As the two installed Cruiser 140-Amp Alternators could overcharge the LiFePO4 batteries (280 Amps into a maximum 205 Amp House-Bank), Electromaax connected through the internet and their User System Interface (USI) application to reduce the Alternator maximum output to 60% of capacity; enabling the Alternators to operate at a less strenuous output and reducing their combined output to below the House-Bank maximum charge rate. Still, the House-Bank could be fully recharged in less than 2 hours of motoring.

Corrective Action:

(1) As designed and planned, the House-Bank was being fully recharged in under two hours of motoring. However, 10-15 minutes after the Alternators stopped charging the LiFePO4 batteries would all disconnect requiring a re-set of their Battery Management System. To their excellent credit Electromaax assembled the same configuration in their shop and confirmed the same unexpected result. After a week of Electromaax research and testing it was resolved that our specific configuration required a fourth LiFePO4 battery. Upon installation of the fourth LiFePO4 battery the entire system is now operating perfectly.

Conclusion

The Electromaax Sales and Technical support throughout our installation was excellent.

It is understood that this was the first Volvo TMDxx Pulley Kit conversion performed by Electromaax, and the first use of dual Cruiser Alternators through the E-MAAX PLUS components into the G31 LiFePO4 batteries. Excepting for our trial and error process to modify the Volvo engine Alternator Mounts, the entire installation was straight forward.

Last year after a few days away from shore power, even running the Generator for several hours a day, our undercharged House-Bank could not keep the Fridge/Freezer fully working. This year with the Electromaax upgrade we operate the Generator far less and have a fully charged house-bank shortly after 90 minutes of motoring which keeps the Fridge/Freeze and all other items operating through 24 hours and more.